The term C-parts or C-items refers to materials that are only indirectly used in the production or provision of services by companies, i.e. production-related products that are not directly incorporated into the product.

These goods include, for example:

- Personal protective equipment (PPE)

- Office supplies

- Tools

- Workwear

- Technical products

- Abrasives

Properties of C-parts

C-parts typically have the following characteristics:

- Low material costs

- Small batch sizes per order

- Many manufacturers and suppliers

- High product diversification

- High proportion of procurement costs

The C-parts dilemma

These materials usually have a very low value at a comparatively high procurement cost.

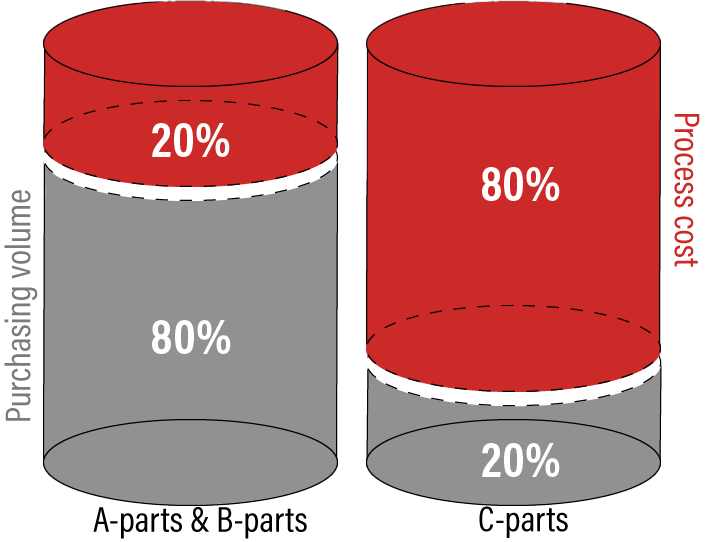

Experience shows that C-parts account for only about 20% of material costs but cause 80% of process costs (Pareto effect). According to the Pareto effect, the purchase volume is only a very small part of the total volume.

The contribution of auxiliary and operating materials to the direct success of the business is small. Sourcing, organising replenishment and quality control are often unmanageable. The procurement of C-parts distracts from the real value-adding processes. At the same time, it is these undervalued items that make an efficient work process possible in the first place. This is where effective and, above all, economical C-parts management plays a major role in saving process costs.

Identifying C-parts – the ABC analysis

To classify goods in a company according to the ratio of consumption quantity to material value, they are categorised as A, B and C-parts:

- A-parts: low consumption, high material value

- B-parts: medium consumption, medium material value

- C-parts high consumption, low material value

How does the C-parts analysis work at AWI?

Step 1

Creating a database

The analysis begins with a data collection of all the company’s existing procurers. The next step is to collate the data, either by the company itself or by AWI. The data is harmonised by AWI and prepared in a data base for analysis.

Step 2

Analysing the data

AWI uses the procurement frequencyto analyse which items represent a recurring requirement. These items are ideal for AWI to take over the C-parts management. Experience shows that approximately 10 to 15% of the original data is omitted because it does not represent true C-parts (e.g. system parts, small machines or one-off requirements). The identified portfolio is then agreed with the customer.

Step 3

Defining the portfolio

The product database agreed with the customer defines the

C-parts portfolio that AWI will cover in the future. Additional C-parts can be added to the existing product range at any time and existing products can be appropriately substituted.

AWI also supplies C-parts with specific product requirements

Not all C-parts can simply be stored at any temperature for an unlimited period of time. Some items require special storage to maintain their product properties. For example, there are adhesive tapes with a ‘best before’ date, or films that only need to be stored within a certain temperature range. For such specific requirements, in addition to ensuring correct storage, appropriate documentation must be kept. At AWI we use a form of digital backup for this purpose. This not only acts as a warning system if certain values are under or overshot, but also takes care of the documentation of correct storage. To ensure correct storage, the warning systems also include tolerance values to allow sufficient time for action. We also supply product groups that are classified as dangerous goods.

C-parts management

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers. More Information